Innovative Polymers: Reinventing Modern Production

Innovative Polymers: Reinventing Modern Production

Blog Article

Optimizing the Prospective of Polymers: Discover the Diverse Advantages and Practical Utilizes

The complex advantages and useful uses of polymers proceed to progress, providing ingenious options to complex difficulties. By discovering exactly how polymers can improve item resilience, drive sustainability efforts, reinvent medical care remedies, and pave the method for future technological advancements, we can uncover a world of possibilities waiting to be harnessed.

Relevance of Polymers in Modern Industries

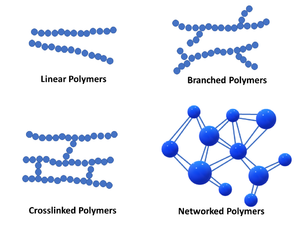

Polymers play a critical role in modern markets, functioning as flexible materials that drive innovation and performance across a large range of markets. These intricate particles, composed of duplicated subunits, have actually changed industries such as automobile, aerospace, electronics, medical care, and a lot more. In the vehicle field, polymers have actually made it possible for the advancement of lightweight yet resilient parts, boosting gas effectiveness and general performance. Aerospace sectors rely upon polymers for their high strength-to-weight ratio, important for airplane and spacecraft building. The electronic devices market advantages from the insulating buildings of polymers, crucial for manufacturing motherboard and digital tools (Polymers). Additionally, polymers are thoroughly made use of in the healthcare field for medication distribution systems, clinical tools, and biocompatible materials. Their adaptability, durability, and cost-effectiveness make polymers indispensable in modern production processes, fostering advancements and driving progress in numerous industries worldwide. Embracing the possibility of polymers is crucial to unlocking further technologies and resolving the advancing requirements of today's industrial landscape.

Enhancing Product Durability With Polymers

With an emphasis on durability and resilience, incorporating advanced polymer modern technologies right into product design has become a cornerstone of enhancing durability in contemporary manufacturing procedures. Polymers provide a wide variety of properties that add to the total resilience of products. One crucial benefit is their resistance to deterioration, chemicals, and weathering, making them perfect for usage in numerous industries where exposure to severe problems is typical.

In addition, polymers can be customized to satisfy particular longevity requirements, enabling suppliers to tailor items according to their planned use and anticipated lifespan. By incorporating polymers into product elements, suppliers can improve strength and effect resistance, reducing the chance of damage or put on in time.

Additionally, polymers are light-weight yet durable, giving durability without including unneeded weight to items. This characteristic is especially beneficial in markets such as aerospace and auto, where lightweight products are crucial for enhancing gas performance and total performance.

Sustainability Innovations Through Polymer Technology

In the realm of modern manufacturing and product layout, the cutting-edge application of polymers is driving significant improvements in sustainability techniques. Polymer technology plays an essential role in enhancing sustainability by using services that decrease ecological influence throughout different sectors. One essential aspect where polymers stand out is in enabling the development of lightweight yet sturdy materials that add to fuel effectiveness in transport and minimize total energy consumption. Additionally, the recyclability and biodegradability of particular polymers better promote sustainable practices by reducing waste and air pollution.

Furthermore, improvements in polymer innovation have brought about the development of bio-based and eco-friendly polymers, derived from natural resources such as plants, that use a more lasting alternative to typical petroleum-based plastics. These eco-friendly polymers not just help lower reliance on fossil fuels yet likewise decrease greenhouse gas emissions throughout manufacturing. By integrating these ingenious polymers right into manufacturing procedures, companies can minimize their environmental impact and relocate towards more sustainable methods, lining up with global initiatives to deal with climate adjustment and promote a round economic climate.

Polymers in Health Care: Revolutionizing Medical Solutions

Among the essential areas where polymers are making substantial strides remains in the growth of targeted medicine distribution systems. By encapsulating drugs within polymeric nanoparticles or micelles, scientists can improve drug security, boost bioavailability, and allow controlled launch, bring about extra reliable therapy routines with lowered side results.

Moreover, polymers are instrumental in the field of regenerative medicine, where they are made use of to produce scaffolds that simulate the extracellular matrix, giving support for cell development and cells regrowth. This technology holds immense guarantee for fixing damaged organs, advertising wound healing, and progressing tailored medication strategies.

Fundamentally, the assimilation of polymers in medical care is driving development, enhancing therapy effectiveness, and ultimately enhancing patient outcomes in ways formerly assumed unattainable.

Future Applications and Developments in Polymer Innovation

Progressing at the leading edge of scientific exploration, polymer innovation proceeds to pave the way for groundbreaking applications and advancements shaping varied industries. In addition, polymer nanocomposites are enhancing the mechanical and thermal residential properties of products, leading to more powerful and lighter elements in aerospace and automotive industries. Looking in advance, scientists are checking out the possibility of shape-memory polymers for applications in robotics and biomedical tools, where materials that can "keep in mind" and click site return to their initial shapes offer amazing possibilities for development.

Conclusion

Report this page